The displacement of the track from its original position is known as buckling of the rail. Buckling takes place due to the development of excessive compressive forces in the track due to insufficient expansion gaps in the track.

Causes of Buckling

Buckling of rails takes place due to the following causes:

- Due to excessive creep – Development of excessive creep throws the track out of its original position.

- Due to insufficient expansion gap – The insufficient gap does not allow the rails to extend fully. resulting in the development of compressive forces in the rails, which throw the rail out of their position.

- Leaving rail closures in rails, particularly when laid in summer season when the temperature is very high.

- Failure to lubricate switch expansion junction in time.

- Due to loose fittings.

- Due to inadequate ballast.

- Due to the use of welded rails on the weak track.

Location of rail Buckling

The following locations are more susceptible to buckling:

- Wooden sleeper track in the vicinity of turnout, insulation joints and switch expansion joints.

- Short stretches of wooden sleeper track on a road.

- Junctions of two tracks one laid with anti-creep fastening on metal sleepers and the other laid on wooden sleepers without anti-creep fastening.

- Wooden sleeper track, between metal sleeper track on one side and level crossing on another side.

Remedial Measure For Buckling

Buckling may be removed by adopting the following measures:

- The ballast section, sleeper density and rail section must be redesigned and should be increased suitably.

- Anti creep fastening should be adopted.

- The number of welded rails should not be very large.

- Provision of steel sleepers or welded rails anchoring should be made.

- Proper lubrication of contact surfaces of fish plates and fish bolt should be done at a regular interval, at least once in two years.

- Sufficient expansion gap between rail joints should be provided.

- The fish bolts should not be tightened too much, so that expansion or contraction may be allowed.

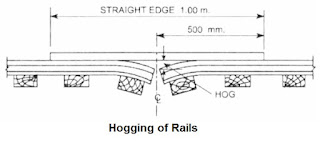

Hogging of Rails

When the rails bent vertically at the ends are known as hogged rails. The hogging of rails is one of the serious defects which develops due to poor maintenance of rails joints, yielding formation, loose and faulty fastenings etc. It causes damage to the running quality of the track. This effect can be remedied by the following measures.

- By replacing the hogged rail.

- If the hogging is small, it can be rectified by measured shovel packing.

- The hogged rails can be improved by welding the worn-out ends.

- The end of the rail is cut about one meter in length and fresh holes are provided for fish plates.

- The vertical bent of the rail is removed by defogging it in the opposite direction with the help of defogging machine

Also, read – Requirements of an Ideal Rail Section

Thanks for reading this article. Please, don’t forget to share it.