Table of Contents

What is Development Length?

It is the minimum length of the bar that must be embedded in concrete beyond any section to develop its full strength.

This is also called an anchorage length in case of axial tension or axial compression and development length in case of flexural tension or flexural compression.

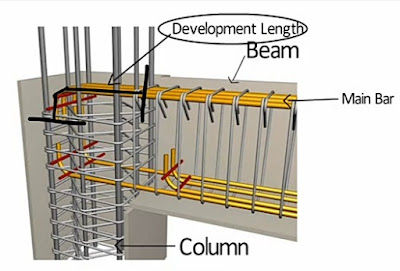

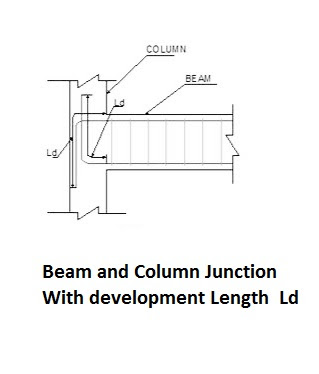

It is provided at column beam joint or column footing joint. Here you can see in the picture this is the development length for the beam-column joint.

The main bar in the beam is extended from here to here (as shown in the image below) to safely transfer stresses from the beam to the column and this portion of length is called development length.

Also, read – What is Lap Length? How to Calculate it? – Complete Guide

Why we provide development length?

It creates a safe bond between bar surface and concrete. It also ensures that during ultimate load conditions, the reinforcement bar should not slip through the concrete.

It transfers stress or loads from Beam to column smoothly now you understood why we provide development length.

What will happen if we don’t provide development length?

If we don’t provide it or if we provide less development length against the required, then the structures will be prone to encounter failure due to slipping of joint.

In such cases, the bars will not break first, but the failure will happen at joints and laps before breaking of reinforcement bars. In short reinforcement bars will split from concrete.

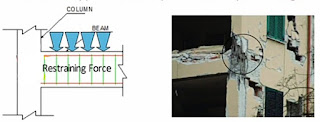

Let us take the case of the beam-column joint in which development length is not provided. If we apply force more than the maximum permissible limit, then the restraining force between the beam and column will not be sufficient to hold the beam at its position.

The beam will come out from the column if the development length is not provided during construction.

The development length is needed to provide support to the beam to reduce the chances of the beam coming out of the concrete column. Hence it acts as a supporting member for the reinforced beam in the concrete column.

Also, Read – Difference Between Lap length and development Length

How to calculate Development Length?

For understanding the concept of bond and development length, let us consider a steel bar embedded in concrete. the bar is subjected to a tensile load T.

Due to the tensile force, the steel bar will tend to come out and slip out of the concrete. This tendency of slipping is resisted by the bond stress developed over the surface of the bar.

Bond stress is the shear stress developed along the contact surface between the reinforcing steel and the surrounding concrete which prevent the bar from slipping out of concrete. To avoid slipping

T ≤ τ bd × 2πφ/2 × Ld (surface area = 2πr × Ld)

T = σ st × π/4 ×φ2 ( T = σ st × Aφ)

σ st × π/4 ×φ2 ≤ τ bd × 2πφ/2 × Ld

Ld ≥ σ st φ/ 4 τ bd

Where

Ld = Embedded length of steel bar

σ st = Permissible stress in steel

τ bd = Bond stress

φ = Diameter of bar

Ld is called the development length and As per code IS 456:2000, it is given by

Ld = σ st φ/4τ bd

This formula is used to calculate the required development length in mm for any given diameter of the bar. The same formula is used for the limit state method as well as the working stress method.

The permissible bond stress τ bd depends upon the grade of concrete and type of steel. The values of permissible bond stress are given in the table.

Also, Read – How to calculate Cutting Length of Stirrups for Beam and Columns.

Permissible Bond Stress For Plain Bars And Deformed Bars

| Grade of Concrete | τ bd For plain bars(N/mm2) | τ bd For deformed bars(N/mm2) |

| M20 | 0.8 | 1.28 |

| M25 | 0.9 | 1.44 |

| M30 | 1.0 | 1.60 |

| M35 | 1.1 | 1.76 |

| M40 and above | 1.2 | 1.92 |

Here

a.) For deformed bars is 60% more than that of plain bars.

b.) It is easier to pull a bar than to push it inside. Therefore permissible bond stress for plain and deformed bars in compression is taken 25% more than that for the bars in tension.

Ld in compression = σ st φ/ 4(1.25) τ bd

= σ st φ/ 5 τ bd

The development length for steel bars of different grades are computed by the following formula and data are given in the table

Ld in tension = σ st φ/ 4 τ bd

Ld in compression = σ st φ/ 5 τ bd

Also, Read – How to Calculate Cement, Sand and Aggregate Quantity in Concrete?

Development Length For Single Bars

1. φ is the diameter of the bar.

2. In the case of bundled bars in contact, the development length is given by that for the individual bars and increased as follows:

- 10% for two bars in contact.

- 20% for three bars in contact.

- 33% for four bars in contact.

Development Length for bundled bars

When there is a large number of bars, required to be provided based on the design it may not be possible to place the bars separately with the necessary clearance. In such cases, there are two options

- Increase the size of the concrete member that is the column or beam

- Bundle the bars in groups of 2, 3 or 4 bars

Here if we consider option number 1 and if we increase the size of the concrete member then there will be a cost implication. So, it’s better to go with option number 2.

If we bundled the bars then these bars will have a low contact area than surrounding concrete when compared to the bar placed separately.

This affects the bonding between concrete and bars, which is often a concern, especially in beams. To fulfil this requirement the development length is increased suitably.

- If two bars are bundled it shall be increased by 10%

- If three bars are bundle then it shall be increased by 20% and

- If four bars are bundled it shall be increased by 33%

Also, Read – Nominal Mix Concrete vs Design Mix Concrete

Factors affect Development length

1. Compressive strength of concrete

The development length required for bars is inversely proportional to the compressive strength of concrete which means if more is the compressive strength then less would be required development length.

2. Density of concrete

If lightweight concrete is used then it must be increased.

3. Rebar clear cover

If we increase clear cover then it will decrease.

4. Rebar centre to centre spacing

If the bar spacing is increased then more concrete will be available for rebar to resist horizontal splitting.

In beams, bars are closely spaced one or two bars diameter apart. On the other hand for slab footing and certain other types of members, bar spacing is higher, and thus required development length is less.

5. Coating of Rebar

Sometimes in some projects where the structure is subjected to corrosion environmental conditions there epoxy coated rebars are used instead of normal rebars.

Studies have shown that in such cases the bond strength between concrete and rebar is reduced and thus more development length is required.

6. Rebar diameter

The most important and common factor that would influence development length is the diameter of reinforcement is used.

It has been observed that smaller diameter bars require lower development length than larger diameter bars.

Conclusion

So, friends, I hope I have covered all the information about development length in this article.

If you learnt something from it, please be sure to share it with someone who might benefit from it.

If you want to add any information which has been missed in this article you can mention it in the comment section.

Finally, Thanks for reading this article.

FAQs

What is Development Length?

It is the steel bar length required to be inserted into the concrete to develop the desired bond strength. This steel bar length holds two concrete members together like beam and column.

What is Development Length Formula?

As per IS456:2000, the formula for Calculating development length is Ld = σ st φ/4τ bd

Where

Ld = Embedded length of steel bar

σ st = Permissible stress in steel

τ bd = Bond stress

φ = Diameter of bar

Usually, in practice, the development length requirement is expressed as 41D, where 41 is the constant factor calculated using the above formula and D is the bar diameter.

What is the difference between development length and Lap length?

Development length is provided to safely transfer stress/load from steel bar to concrete. In comparison, Lap length is provided to transfer load from one bar to another safely.

What is the difference between development length and anchorage length?

Development length is the bar length required to transfer stress/load from steel bar to concrete. In comparison, Anchorage length is provided if adequate development length can’t be provided inside the fixed end/support. It is usually considered as 8 times of bar diameter.

Also, Read

Pre-stressed Concrete – Definition, Method, Advantages and Disadvantages.

Difference Between Pre Tensioning and Post tensioning.

Concrete Mix Ratio, Types, Proportioning of Concrete Mix & Methods

What is Workability of Concrete? Factors affecting workability of concrete.

Density of Cement, Sand and Aggregate, Bulk Density of Aggregate

What is Plinth Beam? – Plinth Protection, Difference Between Plinth Beam and Tie Beam

The very nice article it gives value for civil engineers I always in confusion both development length and lap length but the now confusion is clear

thanks for writing this article

Thanks for your valuable feedback.

Thank you for sharing your info. I truly appreciate your efforts and I will be waiting for your next post thanks once again.|

Thanks for your valuable feedback.