Table of Contents

Specific Gravity of Cement

As we know that the specific gravity of ordinary portland cement is between 3.1 to 3.15 g/cc and for portland pozzolana cement and portland blast furnace cement it is near to 2.90 ( As per Portland Cement Association -PCA 1998)

What is specific gravity?

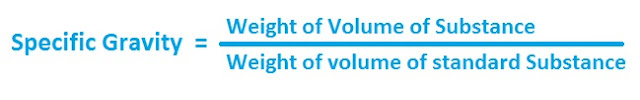

The specific gravity of any substance may be defined as the ratio of its specific weight of given volume to that of a standard substance of the same volume at a standard temperature.

Mostly, the standard substance is taken water at 4° C. For gases, the air is taken as standard at 25°C. But in the case of cement water is not used because cement reacts with water and form calcium oxide.

With cement, kerosine is used as the standard substance because kerosine does not show any reaction with cement.

We found out the specific gravity of any material to know the behaviour of the material in water whether it will sink or float in water.

All kind of material has a fixed specific gravity which ranges from 1 to 100.

If a material has a specific gravity less than 1 then it will float on water and if a material has specific gravity more than one then it will sink in water. So, with the help of specific gravity, we can choose a material for a specific purpose.

Essentially specific gravity gives us an idea about material whether it is heavier or lighter with respect to water. The specific gravity of OPC cement is 3.1 to 3.16 g/cc that means cement is heavier than the water of the same volume and it sinks in water.

Specific Gravity Formula

Importance of specific gravity of Cement

Cement particles contain pores which may contain moisture content due to extreme weather conditions. Which my rise the specific gravity of cement. Ones the specific gravity reaches 3.19 then pores are filled with moisture and chemical reaction take place this process is called hydration.

Moisture is the biggest enemy of cement. Once cement hydrated with water, it becomes useless. This is the reason that’s why lots of lumps are formed in the old stock of cement due to moisture content.

Specific gravity value more than 3.19 indicates that cement was not properly minced into powder form during its production or cement has more moisture content

Generally, a nominal mix is prepared with the cement of specific gravity 3.15. if there is any change in this value it will affect the design mix. It may increase the water-cement ratio which will affect the workability and strength of concrete.

Specific Gravity of Cement Test

Object:- To determine the specific gravity of a given cement sample.

Apparatus required

- Specific gravity bottle or Le Chatelier flask

- Weighing balance

- Kerosine

Procedure

- Clean and dry the specific gravity bottle and weight it with the stopper W1.

- Fill the specific gravity bottle with cement sample about 50 gm to at least half of the bottle and weigh it with stopper W2.

- Fill the specific gravity bottle containing the cement with kerosine free of water placing the stopper and weight it W3.

- While doing the above experiment do not allow any air bubble to remain in a specific gravity bottle.

- After weighing the bottle the bottle should be cleaned and dried.

- Then fill it with kerosine and weight it with stopperW4.

- All the above weight should be taken at the room temperature of 27° C +_ 10° C.

Observations

| Description of item | Weight in gm | Trial 1 | Trial 2 | Trial 3 |

| Weight of empty dry specific gravity bottle | W1 | |||

| Weight of bottle + cement (filled 1/4 to 1/3) | W2 | |||

| Weight of bottle + cement (partially filled) + kerosine | W3 | |||

| Weight of bottle + Kerosine (Full) | W4 |

Calculations

The specific gravity of Cement (Sg) = (W2 – W1) / (W2 – W1) – (W4 – W5) × 0.79

Note – Specific gravity of kerosine = 0.79

Result

The specific gravity of cement is ………..

Precautions

- Only kerosine which is free of water shall be used.

- At the time of weighing, the apparatus will not be allowed to exceed the specified temperature.

- All air bubbles should be eliminated in filling the apparatus and inserting the stopper.

- Weighing should be done quickly after filling the apparatus and should be accurate to 0.1 mg.

If you found this article helpful, please share it with your friends.

Thanks!