Table of Contents

What is AAC Block?

Autoclaved aerated concrete AAC has many names like autoclaved cellular concrete, autoclaved lightweight concrete, porous concrete, aircrete, etc.

AAC is lightweight precast foam concrete. These blocks are porous, reusable, non-toxic, renewable, and recyclable also.

When AAC was first developed?

AAC was developed in 1924 by a Swedish architect seeking alternate building material with properties like wood.

Wood has qualities like thermal insulation, firm structure, and allow smooth working with it. But wood has certain disadvantages like combustibility, decay, and termite damage.

So AAC has all these properties of wood, and also it is fire and termite resistant.

Advantages of Using AAC Blocks

Lightweight

AAC Blocks are three to four times lighter than traditional brick; therefore, more suitable and cheaper to transport.

AAC Block weighs approximately 50% less than standard concrete masonry block, and usage reduces the overall dead load of the building thereby allowing construction of the taller building

Easy Workability and design flexibility

Blocks can be easily cut drilled nailed Miled and grooved to fit individual requirements available in custom sizes simplifying hydro sanitary and electrical installations such as pipes or ducts, which we can install after the completion of the leading construction.

Also, Read – 10 Best Cement Companies In India

Faster Construction

Reduces construction time by 20% different sizes of blocks helps reduce the number of joints in wall masonry, lighter blocks facilitate more comfortable and faster construction. These blocks are easy to install also set and harden quickly.

Minimum Wastages

AAC blocks have negligible breakage less than 5%; hence utilization of blocks increases.

Thermal insulation and energy-efficient

These blocks allow excellent thermal insulation due to tiny air pores and the thermal mass of blocks. Hence helps in reducing the heating and air conditioning costs of a building.

Eco friendly and sustainable

Mix productive use of recycled Industrial waste is a fly ash non-polluting manufacturing process. The only by-product is steam made of non-toxic ingredients that do not exist gasses.

Also, Read – Difference Between OPC and PPC Cement

Acoustic performance

Superior sound absorption qualities due to the porous structure of the block offer sound attenuation of about 42 decibels blocking out all significant sounds and disturbances ideal for Schools, Hospitals, Hotels, Offices, Multifamily housing, and other structures that require acoustic insulation.

Fire-resistant

AAC blocks are non-combustible and fire-resistant up to 1600 degrees Celsius. These blocks are fire-resistant for approximately 2 to 6 hours, depending on the thickness of the Wall.

Cost-saving

The requirement for plaster on AAC blocks is less due to the surface accuracy of the blocks, thus reducing overall construction cost by 2.5 %.

Since it requires less jointing hence minimizes the demand for cement and steel. AAC block has high insulation properties, which help in saving energy costs by almost 30%.

Variation in sizes of blocks, help in increasing carpet area. Almost Nill efflorescence affects the AAC Blocks permit wall painting and plastering to serve last longer, and this translates into low maintenance costs.

Seismic resistant

The manufacturing process gives the blocks excellent strength maintaining its lightweight property due to which the steadiness of these blocks in buildings is more reliable, making it earthquake resistant.

Also, Read – What is M sand? 20 Properties, Advantages and Disadvantages

Accuracy

ACC blocks offer high precision in size. Blocks are available in exact dimensions to provide a smooth wall with a perfect joint between different elements. It also helps to save cement and steel usage.

Termite pest-resistant

The blocks are made with inorganic materials; hence they keep termites away, avoiding damages and losses.

Water saver

AAC Block walls do not require water for curing. Only the mortar joints need water for curing, thus reducing water consumption.

Blocks size

Following the block, sizes are available in AAC Blocks.

| S.No. | Particulars | Size (L x B x H) in mm |

| 1 | Size 1 | 600×200×200 |

| 2 | Size 2 | 600×200150 |

| 3 | Size 3 | 600×200×100 |

| 4 | Size 4 | 600×300×200 |

| 5 | Size 5 | 600×300×100 |

| 6 | Size 6 | 600×400×250 |

The weight of the standard size of a block, which is 600 × 200 × 200 mm is 15 kg.

Also, Read – Silt Content Test For Sand

Disadvantages of AAC Blocks

- AAC blocks are non-load-bearing material; hence it can be used only for partition walls.

- AAC blocks are well known for cracks after installation, which can be overcome by reducing the mortar strength.

- AAC blocks have brittle nature; therefore, they require more care than clay brick while handling and transporting.

- The cost per unit of AAC block is high, but overall, masonry cost is low because it requires less mortar for installation.

- Its brittle nature requires long thin screws for wall hangings and cabinets and requires a drill bit or hammering in. We have to use a large diameter wall plug, which has a higher cost than a standard plug.

- Northern European countries’ new building codes require a very thick wall if using aac block only. Hence several builders are using traditional building methods for the installation of an extra insulation layer.

- We can’t hammer aac block for the service like chiselling because it may break. Although we can cut aac blocks by the carpenter’s saw easily, it is time-consuming and requires particular labour for this specific work.

Also, Read – What is WPC Board? – Advantages, Disadvantages, Uses

Properties of AAC Block

Oven-dry density is 552 to 650 kg/cum

Compressive strength is 35 to 40 kg/cm2 as per is code 2185

Thermal resistance is 0.8 to 1.25 per inch of thickness

Sound transmission class(STC) is 40 for 4-inch width and 45 for 8-inch width.

property numbers 1 and 2 are essential so keep them in mind

Technical Comparison of Blocks

| Parameter | AAC Block | Concrete Block | Brick |

| Size | (600x200x100-300) mm | (400x200x100-200) mm | (230x115x75) mm |

| Compressive Strength | 30 – 50/Kg/3Cm2 | 40 – 50/Kg/Cm2 | 25 – 30/Kg/Cm2 |

Dry Density | 600-650/Kg/Cum | 1800 Kg/Cum | 1950 Kg/Cum |

Fire Resistance | 4-6/Hour Depending On Thickness | 42Hours | 2Hours |

| Sound Reduction Index(DB) | 60 For 200 mm thick wall | _ | 40 For 230 mm Thick Wall |

| Thermal Conductivity w/(Km) | 0.25 | 0.51 | 0.81 |

Physical Properties of Autoclaved Cellular Concrete Blocks Clauses (4.1,8.3,8.4,8.5,11.2,11.3 and 11.4) IS :2185(Part-3) 1984

| S.No. | Density in oven-dry condition | Compressive strength min grade 1 N/mm2 | Compressive strength min grade 2 N/mm2 | Thermal conductivity in air-dry condition w/MK |

| 1 | 451 to 550 | 2 | 1.5 | 0.21 |

| 2 | 551 to 650 | 4 | 3 | 0.24 |

| 3 | 651 to 750 | 5 | 4 | 0.30 |

| 4 | 751 to 850 | 6 | 5 | 0.37 |

| 5 | 851 to 1000 | 7 | 6 | 0.42 |

Manufacturing Process

AAC is a precast product manufactured by combining pulverized fly ash, gypsum, lime, cement, water, and Aluminium powder poured into a mould.

Once added to the concrete aluminium powder reacts with lime and fly ash resulting in the formation of millions of microscopic hydrogen bubbles.

The hydrogen Bubbles cause the concrete to expand to roughly double The Times of its original volume the hydrogen subsequently evaporates leaving a high closed shale aerated concrete.

Then aerated concrete is cut into blocks which are then steam and pressure cured in an autoclave for 8 to 12 hours.

Also, Read – Difference Between Cement Plaster and Gypsum Plaster

Laying process

Laying of AAC Block masonry shall be as per IS 6041 of 1985 and IS 1905 of 1987. AAC Block laying process is almost similar to brick masonry only a few differences are there

Opening and odd angles should be cut with a handsaw.

Bond beams should be placed at the top of the wall and we can use them for heavy-duty fixture attachment.

The vertical joint shall not be in a straight line.

Overlapping of blocks in the structured course should be a minimum of 250 mm over the bottom course.

Thickness of joints

The thickness of the joint should be kept at 10 mm in case of cement sand traditional mortar if we are using dry mix mortar on AAC blocks then only 3 to 5 mm thick mortar is required.

Here I will tell you about the dry-mix mortar.

A dry mix mortar is a factory mix mortar that contains cement, graded sand and polymers.

Also, Read – Difference Between Veneer and Laminates

Precautions to be taken while laying of AAC masonry

- Do not use the blocks below plinth level like in the foundation, drainage pit, water tank and where excessive dampness is likely. It is the reason we don’t use AAC blocks working toilets and bathroom similar to brick masonry it is not recommended to have an AAC Block wall without stiffeners.

- It is necessary to provide stiffener column after every three-metre length.

- It is recommended to provide RCC band or bond beam after every fourth course (1200 mm height) with steel reinforcement, so the wall load is uniformly distributed to avoid any shear crack and horizontal crack.

- Avoid using AAC blocks for the load-bearing structure that structures where beams and columns are not used.

- Mortar mix should be 1:6 and do not use the rich mortar with 1:4 as this will shrink and will cause cracks in the Wall

- Preferably used Portland pozzolana cement for better results

- Do not store the blocks on the unlabeled surface

Also, Read – Difference Between Ceramic Tiles and Vitrified Tiles

Why do AAC blocks get cracks? And its Prevention

- Brittle Nature – AAC blocks are brittle material due to which it may break easily. Also, they have voids due to which they may break while dropping from a low height.

- Due to dry shrinkage – After manufacturing, aac blocks require 28 days curing and also need to dry for 10 to 15 day to obliterate its expansion and contraction. If manufacturers do not follow this process and deliver material early on-site, then there are more chances of cracks due to expansion and contraction.

- Due to the use of cement mortar– we can use cement mortar as well as an adhesive for the installation of aac blocks. But we should always use adhesive to avoid the development of cracks.

- As per IS code 2185 part-3 AAC block density is 551- 650 kg/m3 and compressive strength is 4 N/mm2 for grade one that means it is non-load bearing material. Hence always provide RCC bend or runner or stiffener of 100 to 150 mm thickness with reinforcement after every 1200 mm height.

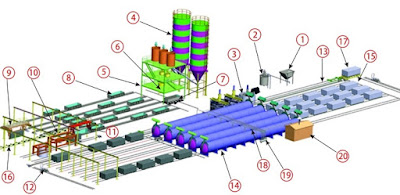

ACC Block Plant

| S.No. | Description | S.No. | Description |

| 1 | Material hopper | 10 | Cutting machine |

| 2 | Slurry making tank | 11 | Tilting crane |

| 3 | Slurry making pit tank | 12 | Windless machine |

| 4 | Silo | 13 | Steam trolley car |

| 5 | Pouring section platform | 14 | Autoclave |

| 6 | Pouring mixer | 15 | Ferry car outlet |

| 7 | Ferry cart | 16 | Side plate return roller system |

| 8 | Mould box | 17 | Finish block dispatch point |

| 9 | Ground crane |

This is a complete post about AAC Blocks. I have tried to cover all the information about AAC Blocks and AAC block masonry. I hope now you have great knowledge about it.

If you liked this article, please share it.

Thanks

Also, read

Pre-stressed Concrete – Definition, Method, Advantages and Disadvantages

Difference Between Pre Tensioning and Post Tensioning

Difference Between Brick Masonry and Stone Masonry

Concrete Mix Ratio – Types, Proportioning of Concrete Mix and Methods

Epoxy Flooring – Types, Uses, Advantages and Disadvantages

Standard Brick Sizes – Importance, Types & Tolerance

I like how you wrote about AAC Blocks – Properties,

Advantages, Manufacturing and Laying Process.

Thanks and keep it up!

Thanks for your valuable feedback.

Good information.. Thank you

Great Info, appreciated.

Please also share the ratio of raw materials and how that be mixed??also the temperature for steaming AAC blocks??

I will be very thankful to you if you reply/guide through e mail.

Regards.

Thanks for your valuable feedback; I am grateful you find my content helpful. I will update the article soon, and also I will try to mail the AAC Block guide as quickly as possible.

Thanks a lot for the article. It’s very useful.

Please tell us about watering the aac blocks before and after laying them. That is, how long we should immerse the blocks in water (just as we do in the case of bricks) before laying, and how long should we give water (to wall) after laying them (it’s said brick walls need to be watered for at least 14 days).

Chhuana, India.

Thanks for your valuable feedback. I am grateful you find my article helpful.

AAC blocks do not require curing or watering before and after laying them. You don’t need to immerse the block in water as you do with conventional bricks.

Before applying the mortar, sprinkle the water on its surface or apply water with a brush.

If you use adhesive or ready mix mortar for joining AAC blocks, it doesn’t require curing, but if you use cement mortar for joining AAC blocks, then cement mortar requires curing.

The adhesive used for AAC block dries up in 4 hours, forming a solid bond without curing. Only cement mortar joint require curing and not needed for ready-mix mortar jointing.

I hope it helps you.

Thanks!